With over 200 experienced and professional employees, state-of-the-art equipment,research labs and pilot plant, we handle various reactions in batchwise and continuous operations.We operate under cGMP and ICH guideline

Stirred-tank reactors

- 28 in SS316

- 32 in G/L

- 3 in Hastelloy

- Total vol. = 300,500 liters

- Temperature = -20 ~ 160 ℃

- Pressure: FV ~ 6Kg/cm2

Ion-exchange columns

Supportive systems

- Purified water system

- Power generators for back-up

Centrifuges (in clean rooms)

- 3 Inverting filter centrifuges in HC

- 1 Inverting filter centrifuge in SUS316

- 1 Horizontal in HC22

- 1 vertical in HC22

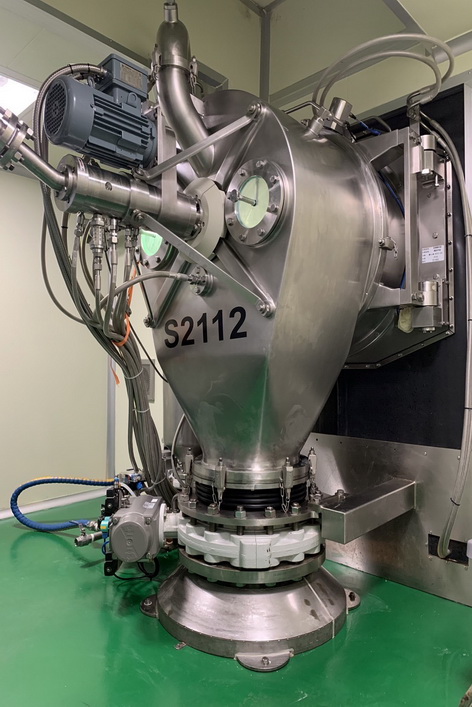

Dryers (in clean rooms)

- 1 Spherical in Hastelloy

- 3 Double helix cone in SUS316 & Hastelloy

- 1 Rotary in SUS316

Mills (in clean rooms)

- 4 Universal

- 1 Jet Mill in SUS316

Distillation systems

- 6 x 8,000 L in SUS316

- 3 x 5,000L in SUS316

- 1 x 4,000 L in G/L

- 1 x 3,000L in G/L

- Vacuum: down to 0.1 torr.

- Temperature: up to 170 ℃

In-process analytical lab

- Qualified Analysts: 10

- Qualified instruments

- Validated methods

- 3 shifts/day coverage